|

- Lightning Molds -

Molds start as blocks of 6061 aluminum, faced and doweled together, then squared up to size. The mold is then opened and cavities are machined into the aluminum. Sometimes a cavity cannot be directly machined and must be cut using a sinker EDM. This requires a graphite exactly the reverse of the cavity desired. Graphite is abrasive to machine and a vacuum is used to collect the dust. Carbide ball mills covered with diamond dust are used to machine the graphite. After the cavities are formed, the mold halves are drilled and tapped to hold the mold together while being injected under high pressure. The mold is then opened and polished and the gates and vents are cut.

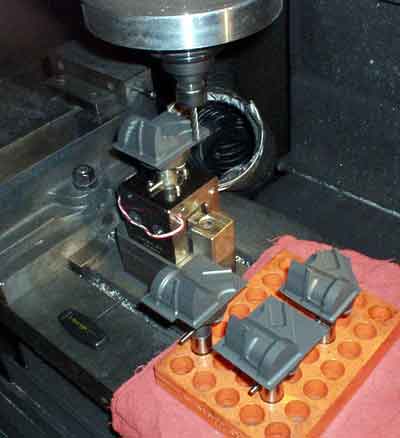

Some of the equipment used to create the molds

CNC Mill cutting EDM graphics for front pivot mold. Note metal vacuum duct removing dust.

Carbide and Diamond dust ball mill carving graphite

Completed front pivot mold being assembled

Waxes packed for shipment to foundry

Wax Patterns ready to be shipped to Foundry

The KCL "Timer Bracket". This is the heart of the "gearless" timing mechanism and is cast in steel.

top

© Morrison and Marvin - all rights reserved |